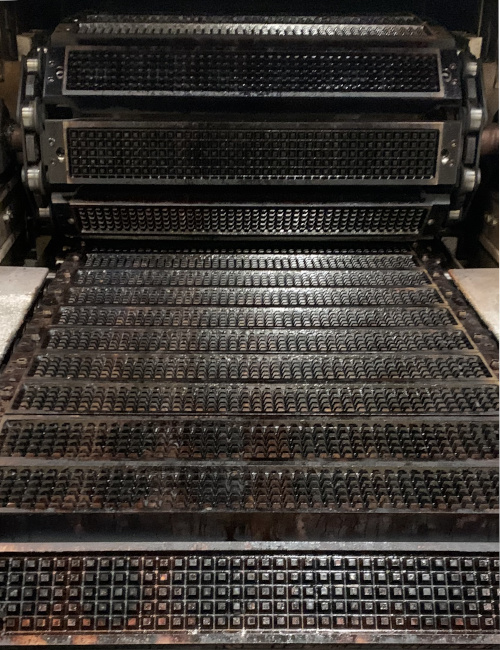

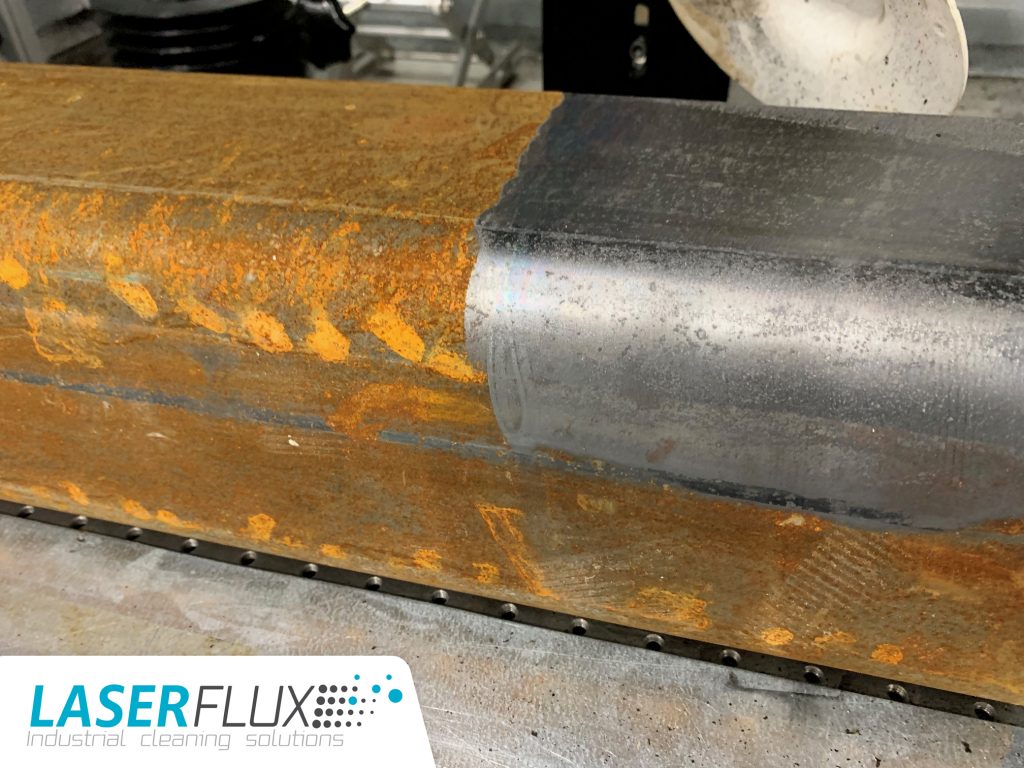

Laser cleaning is THE solution for industrial cleaning

Suitable for rust, paint, coatings and other contaminants

Quick cleaning without disassembly

Laser cleaning usually doesn’t require disassembly, the area stays clean and there is less cleaning needed because of the high degree cleanliness.

Because of all this, the production has to be stopped less often and for a shorter period of time. With an in-line laser cleaning installation, you will have no production stop anymore!

No material flying around

By cleaning with light, there will be no material or residue flying around. The surrounding machines will stay clean and there is no production hall. Perfect for sectors such as the food industry, pharma industry and chemistry.

Save time and money

Every hour of your parts being in maintenance, costs money. With laser cleaning, your parts will get cleaned quickly and efficiently. It goes as quick as sandblasting, but now without all the inconveniences. And without any wear on the parts!

We are happy to help you with your case by making a cost analysis.

No damage to the material

Other cleaning methods, like sandblasting or chemical cleaning, often cause wear on the parts.

This is over for good with laser cleaning. Your parts will be perfectly cleaned without any damage or wear on the underlying material. Even the most stubborn dirt will be removed. This results in a longer life for your molds, gears, driveshaft, etc.

More information?

Are you interested in laser cleaning? Request your free demo via the button below to experience all the benefits of laser cleaning.