Grease residues are known for their difficult removal in industrial environments as well as in private environments. Grease and oil have the advantage that they’re usually dark or completely black when they need to be removed. This is ideal for laser cleaning. A dark, contaminated layer absorbs the heat of the laser beam quickly and evaporates without damaging the material around. We would love to give some examples.

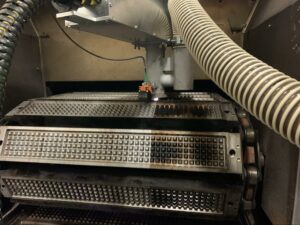

Oil, butter and other sorts of grease are very suitable as a non-sticky coating and are used very often in the food industry (next to synthetic coatings). The disadvantage is that these products get contaminated or start to lose their effect after a few days or weeks. On that very moment, they should be removed and refreshed for taste and hygiene reasons. This piece of grease or oil can be very persistent and requires aggressive or time-consuming cleaning techniques. The bakery world often uses pyrolysis, dry ice blasting or water under very high pressure to remove it. These techniques unfortunately don’t always work as well as expected and also have a major impact on the environment (dust, noise, dirt flying around). Laser cleaning is perfect for a quick and thorough removal of these sorts of grease residues found in a food environment. While performing the cleaning, the rest of the production can continue to do their work.

Oil and grease are still used a lot as a lubricant for bearings, shafts and other moving parts. After a longer period of time it can get very difficult to remove these grease and oil residues. Especially if they are mixed with other dirt from the environment. This hard stuff can be very persistent and settles in small corners and edges of the parts. Laser cleaning is very suitable to remove grease residues (which are not several millimeters thick) very thoroughly down to the smallest corners, crevices, slots, etc. You’re able to clean a part in only a few mintues when normally you’d spend a few hours on it if you would do it manually.

Grease and oil can go deep into many materials. These sort of stains can be very persistent and become more and more difficult to remove over time. With laser cleaning this is possible though, the laser beam will evaporate the oil or grease without damaging the underlying material. By gently adjusting the power and pulse lengths of the laser, you’re able to work very precisely and find the right setting where you completely get rid of the stain without damaging the surface. Laser cleaning can be used on many sorts of wood, stone, metal, glass, etc. Take a look at this page if you want to know more about which materials are suitbale for laser cleaning.

Contact us via the contact form below for more information!

Interested in laser cleaning? Experience a free demo at our demo center to see all the advantages of laser cleaning for yourself.